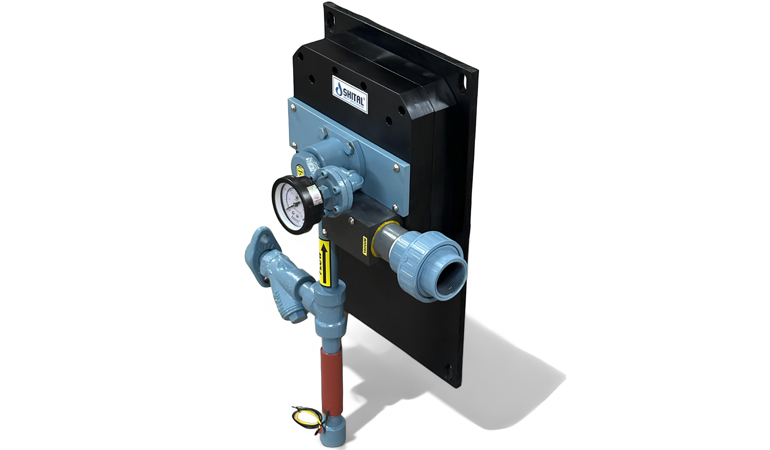

Floor Mounted

Shital Model No (Ranges from FMR-1000 to FMR-3000) is the advance technology Chlorinator designed to feed chlorine gas at a controlled rate. The flow rate of gas is maintained by constant positive acting spring-opposed diaphragm regulators.

Special Features:

1. VACUUM REGULATORS

operate on diaphragm backed by Monel spring vacuum regulator remotely mounted on manifold consisting of electrically operated heater for smooth flow of gas in cold climate; and as such, system remains under vacuum condition till dosing point.

2. DIFFERENTIAL REGULATOR (Optional):

Maintains stedy flow rate and maintains constant vacuum beteween rate valve and flow meter.

3. RATE SETTING :

Manual adjustment at the rate valve located on differential regulator body along with flow indicator.

4. CAPACITY :

10 Kg/hr to 120 Kg./Hr. or 10,000 P.P.D. (Pounds/Chlorine per 24 Hours)

5. RANGE :

Within the basic 120 Kg./Hr. Capacity, the SHITAL Chlorinator is capable of operating overflow ranges from 20 to 1,which are dependent upon the type of flow meters used.

6. WATER REQUIREMENT :

The water supply flow rate and pressure requirement depend upon the maximum Chlorine capacity and back pressure at the outlet of the ejector. Back pressure includes the pipe functional losses between SHITAL Chlorinator and the point of application, plus existing back pressure at the point of application.

7. SEMI AUTOMATIC OPERATION :

The Chlorine regulator will permit gas flow only when the ejector furnishes sufficient vacuum. To operate the Chlorinator, it is necessary to initiate the ejector water flow. To stop Chlorinator, it is necessary to interrupt the water flow. This 'On/Off' operation makes Chlorinator semiautomatic. it can be accompanied by opening and closing of a solenoid valve in the injector water line.